“In addition to energy-efficiency, environmental friendliness, strength and survivability, these Dome Shells have many other benefits, which include unique construction process that saves both money and time”

Pardeep Singh Bali

A team of young technocrats in Jammu, under the banner of Spur Dshelters, have introduced first of its kind Dome-Shelters, claiming it to be the potential game-changer for J&K tourism and affordable housing in the remote- rural landscape.

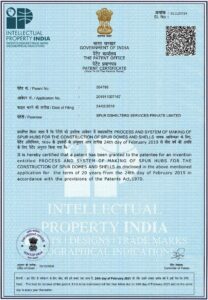

Their process of making spur domes has been patented by the Government of India under Intellectual Property Act and is registered under Start-up India programme.

“The process of making spur domes is first of its kind in the world and that is why it has been patented,” said Ar Vivek Sagar Sharma, the mentor, motivator and chief-inventor of team Spur D.

Ar Aastha and Paras Singh are the main office bearers and Directors of Spur Dshelters Services Private Limited.

Paras Singh stated that they envisaged this venture in 2014 and currently they are working on the project ‘Ik Gran – Holiday Homes’ in District Udhampur, which shall have 27 domes and six have been already completed.

“The Dome Shell has strength that produces endurance. Its lifespan is measured in centuries, not years. In fact, right now, we don’t know just the exact longevity of these domes, but we do know that it is a structure that can be designed and constructed to be passed down to and used by generations,” said Ar Aastha, adding that it has easy and economical maintenance.

In addition to energy-efficiency, environmental friendliness, strength and survivability, the Dome Shells have many other benefits, which include unique construction processthat saves both money and time. A dome’s interior can be planned and designed for any activity or use and with virtually any theme.

“The Dome shell is a micro-energy user. It needs a minimum of energy to maintain a comfortable interior, usually one fourth of that used by other types of structures. In fact, it takes less energy to heat or cool a Dome than it does to heat or cool a super-insulated metal building or a conventional house blanketed in an airtight wrap,” Ar Aastha said and added that people admire Dome Shells for many different reasons. Some like their graceful, curved lines. Others admire their open, clear-span interiors. Still others become fascinated with the technical aspects of Dome construction.

“It is eco-friendly by virtue of its form and by virtue of the fact that it is fully ventilated and makes least use of natural resources. It is earthquake proof, wind-storm proof and naturally appealing due to its unique designs,” said Paras, adding that it has huge tourism potential, as its built appeals tourists and people wish to spend time in these Dome Shells.

The Dome has many different aspects that make it the best choice in construction. Domes are extremely durable and strong. They are fire, water, and wind resistant, making them resistant to many life threatening natural disasters. “The Dome is not only disaster proof, but also extremely efficient. The dome structure allows for a wide variety of floor plan designs because it needs no predefined internal structural support. This allows you to take advantage of the wide open space of your building,” said Ar Aastha, adding that the space can be utilized for remote and rural housing, restaurants and hotels, affordable housing, Panchayat Ghar, dispensary, and roadside shelters.

She asserted that because of its structure, Dome conserves vast amounts of energy, making it more cost effective to run and heat. “A dome is also significantly easier to maintain than a regular building. There is no worry about roof repairs, wood rot, termite damage or any other sort of inconvenient maintenance required in conventional structures,” Ar Aastha claimed. She added that as of now they provide domes of maximum 30 ft diameter and can be constructed anywhere having human accessibility.

“This is a thin shell structure project and it comes in all shapes and sizes. It has double layering, inner layer of Fibrous materials (or natural fibers like jute) and outer layer of thin concrete with iron wires and mashes, making the structure tight and strong,” said Paras, adding that the structure can be designed for horizontal expansion to any stretch, but as of now they are not working on vertical expansion.

He maintained, “Our current technology products, i.e. Type A1-235, SG5.0 or SG6.0 Dome Shell, has the right kind of ingredients of technology and planning, to enable a community to build their own infrastructure, which will be native, modern, sturdy, safe and world class: all at the same time.”

If the Government waives off taxes involved during the parts of the manufacture and construction, the total cost of one SG5.0, A1-235 or SG6.0 type shells can be easily managed around: 1.0 to 1.5 Lakhs per unit in and around any kind of rural set up in India. This cost may further reduce with the progression of work. Such structures can be named as: Community Eco Structures.

“The best part is that the construction of such Community-Eco-Structures will help revive rural economy and ecology. It will bring a new option to the desiring community and a beautify novelty to the rural landscape,” said Ar Vivek, adding that it will have a real cascading effect as a free-for-all, non-monopoly industry will flourish, leading to a great new scope of innovations in materials and their use.

This process of making Spur Dome Shells has three major components, including Hub, Spur and Layering. The spurs are made up of Bamboo, which makes the construction economical, safe, natural and durable.

The team is looking forward to using this technology for construction of grain silos and mud domes. They are also working in the direction of incorporating world class products and innovations like: green concrete as well.